About us

Core Value

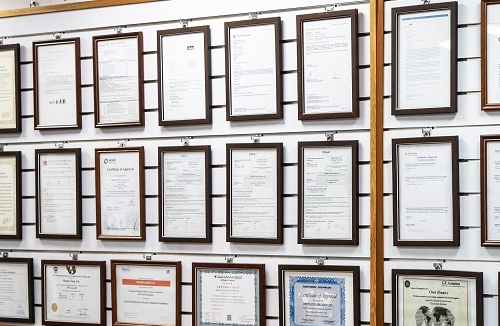

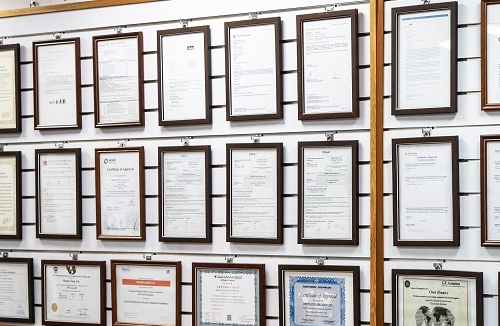

Certifications

Home | About us | Quality

Strictly Adhere to the procedure

--Know the customer spec requirement, then follow it and apply it.

Find the root cause of the problem

-- Correct it, improve it and track it.

Satisfy the customer needs

--Get the customer demand and work to meet the quality, delivery and cost target.

About us

Core Value

Certifications

About us

Core Value

Certifications

Home | About us | Business

Business

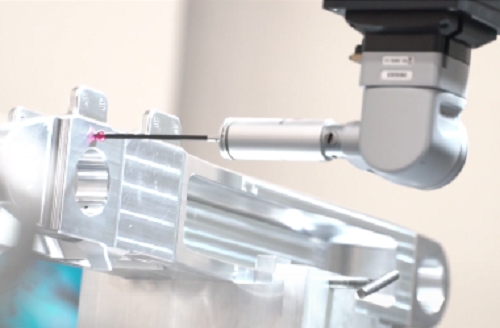

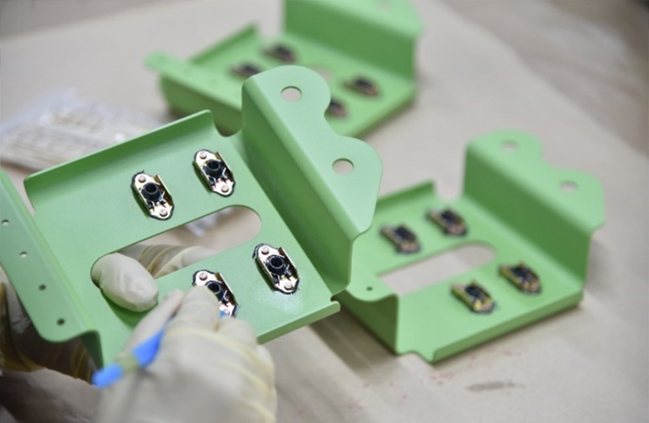

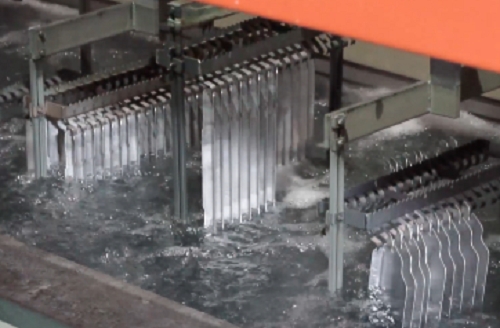

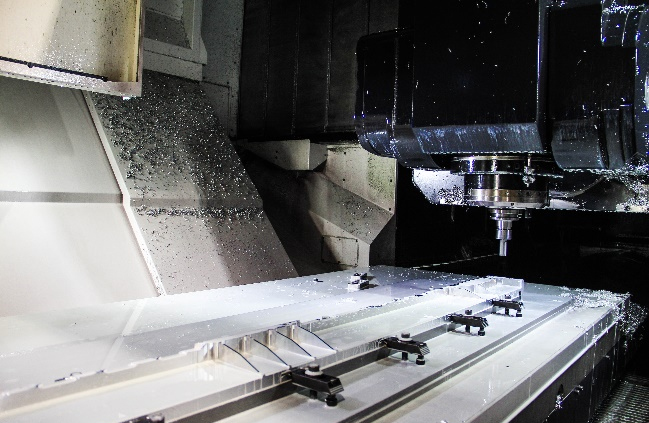

We produce aero structural parts, engine parts and special tools. These parts are delivered to the world's major aircraft manufacturers.

Main Products

(1) Aero structual parts.

(2) Aircraft engine parts.

(3) Landing gear parts.

(4) Special Tools.

About us

Core Value

Certifications

About us

Core Value

Certifications

Home | About us | Strategy

In the global aerospace supply chain

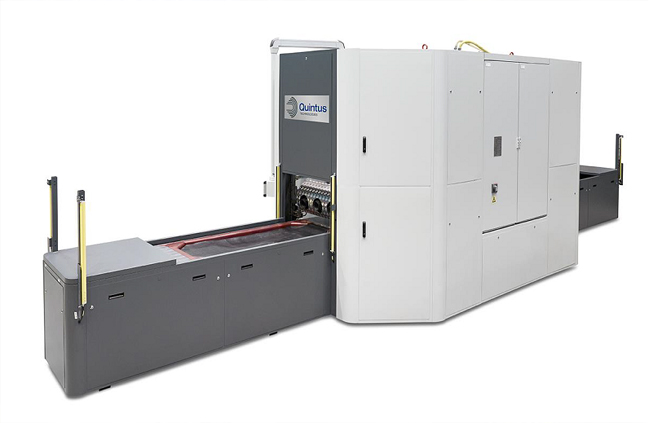

DPI is the one with fully integrated service in machining, sheet metal forming and special processes.

We are able to provide finished parts and acting as your one-stop-shop supplier.

Our strategy for future development will be

Product Strategy

Provide full manufacturing service and expand into assembly

Technical Strategy

Set up more processes with customer demands on aerospace, make it even more complete.

Cost Strategy

Keep improving by the approach of digitized management and smart manufacturing. To keep the competence on the market.

Customer Development Strategy

Keep the current US&Asia business and enhance Europe buiness, to build a stronghold structure for DPI.

Supply Chain Strategy

By the growing of DPI, to creat opportunities with subsidary suppliers for the target of Win-Win.

About us

Core Value

Certifications

About us

Core Value

Certifications

Home | About us | Philisophy

Become a major player in the global aerospace supply chain.

Treat our customers and suppliers with sincerity and form a partnership.

Work together to innovate for the aerospace and strive for greater business opportunities.

In order to achieve this vision,

We must ensure our capabilities as below.

Quality

Ensure the quality of products and services, and do our best to meet the customer demands.

Improvement

Continuously learn and innovate, pursue for better technology, and pay attention to the enhancement of quality and process.

Mutual Benefit

Sincerely treat the employee, customers and suppliers. Provide cooperation opportunity and make it mutual beneficial.

About us

Core Value

Certifications

About us

Core Value

Certifications

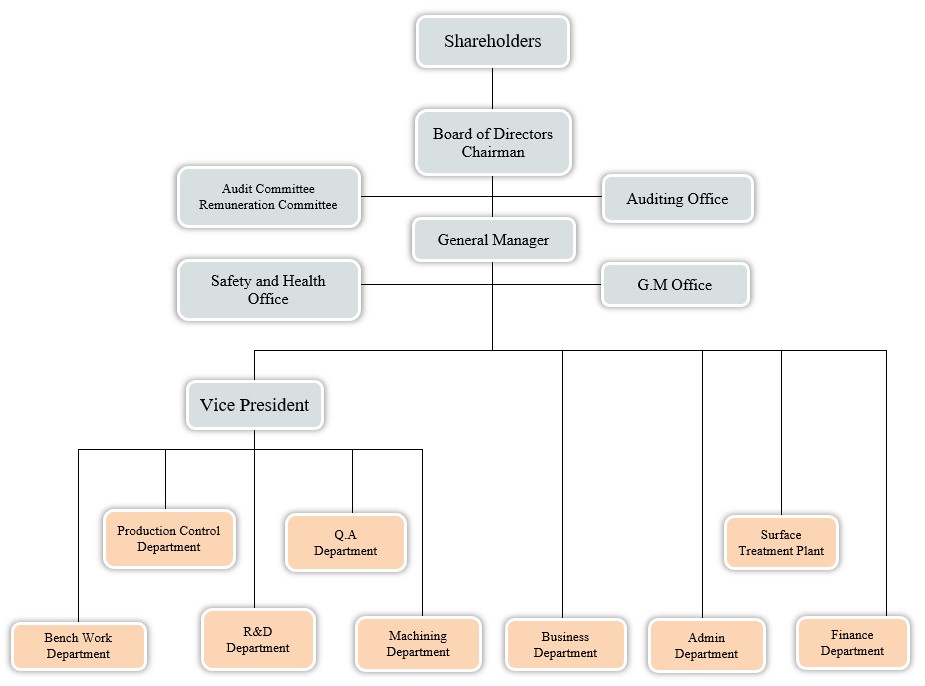

Home | About us | Organization

About us

Core Value

Certifications

About us

Core Value

Certifications

Home | About us | History

| 2019 |

|

| 2018 |

|

| 2017 |

|

| 2016 |

|

| 2015 |

|

| 2013 |

|

| 2012 |

|

| 2011 |

|

| 2010 |

|

| 2008 |

|

| 2007 |

|

| 2006 |

|

| 2005 |

|

| 2004 |

|

| 2003 |

|

| 2002 |

|

| 2001 |

|

| 1990~2000 |

|

| 1990 |

|

About us

Core Value

Certifications